Features & Benefits

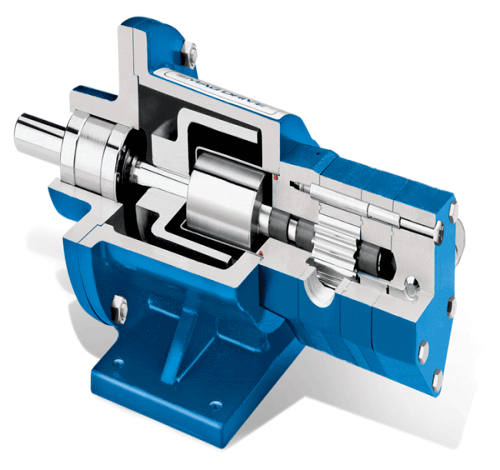

Higher Pressure Capabilities:

Wifth shaft support on both sides of the gears.

Multi-Section Pumps:

Use one motor for multiple pumping applications, blending liquids, or splitting flows to different uses.

Shaft Seal Options:

Including lip seal, component seal, cartridge seal and sealless mag drive options.

Porting Options:

Viking's broadest selection of port locations, configurations, and types.

Compact, Close Coupled Options:

For motor speed operation or with gearmotors.

Minimal Pulsation:

For accurate flow measurement.

Reliable and Easy to Maintain:

With only two moving parts.

One Shaft Seal:

More reliable and lower cost than two used on timed lobe and screw pumps.

Performance

Max. Capacity:

to 190 GPM (45 M3/Hr)

Max. Pressure:

to 2,500 PSI (170 BAR)

Viscosity Range:

28 to 1,000,000 SSU (1 to 250,000 cSt)

Temperature Range:

-40°F to +450°F (-40°C to +230°C)